HOME >Products

Products

SY 200MSF

Product Overview

SY-200MSF is a neutral cured fire-resistant modified sealant. It is a product that exhibits excellent sealing effects against rapid spread of flames and harmful gases through the construction of walls, floor penetration, and linear joints (interlayer fire prevention).

This product is easy to construct and is designed to maintain sealing force even if there is a certain part of joint deformation after construction, and it compensates for the inability to paint, which is a disadvantage of silicon.

Differentiated quality compared to other companies

Excellent durability and excellent waterproofing, dustproofing, and soundproofing due to sealing effects

Compliance with the Ministry of Land, Infrastructure and Transport’s specifications

Strengthening of the Ministry of Land, Infrastructure and Transport’s notification standards / meeting 2 hours (see test report for detailed construction standards)

Complement contraction/stretch/adhesion

This product is designed to secure the shortcomings (contraction, elongation, adhesion) of acrylic (water-based) fireproof sealant

Product characteristics and specifications guide

Differentiated quality compared to other companies

Excellent durability and excellent waterproofing, dustproofing, and soundproofing due to a sealing effect.

Compliance with the Ministry of Land, Infrastructure and Transport's specifications

Meet the fire resistance standards of the Ministry of Land, Infrastructure and Transport for 2 hours (see test report for detailed construction specifications)

Complement contraction/stretch/adhesion

This product is designed to secure the shortcomings (contraction, elongation, adhesion) of acrylic (water-based) fireproof sealant.

| physical properties | Figure | physical properties | Figure |

| Viscosity (#7 × 2.5 rpm) | 1,900,000 cps | Performance temperature range | -50-150°C |

| Color | white. Gray, black | Hardness (ShoreA) | 20± 5 |

| Specific gravity (23°C) | 1.55 ±0.05 | Tensile strength | 1.8~2.2NMASTM D412) |

| Working hours | 30 minutes | Tensile strength | 0.6~_MASTM C1135) |

| slump | None | Elasticity Resilience | 80% or more |

| Touch hardening time*(1) | About 50 minutes | maximum confidence | 400 〜 600% |

| Motion tolerance (%) | ±30% | Workable temperature | 4°C (atmospheric temperature) to 50°C (adhesive temperature) |

| complete hardening | 7 〜 14days | UV/Ozone Resistance | Superiority |

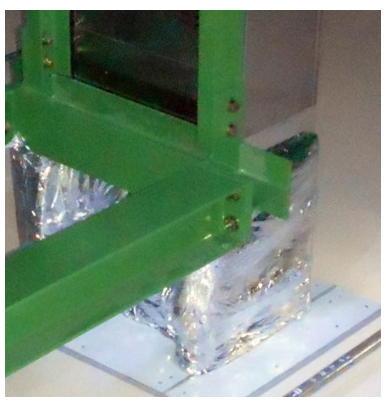

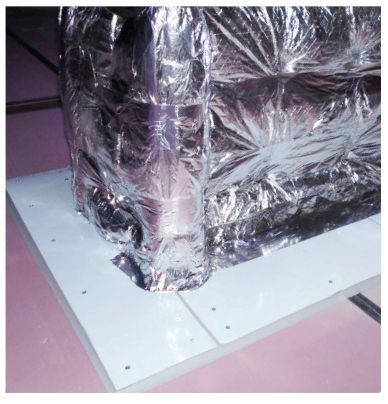

Construction case

case1

case2

case3